Reporter: Theo Kelen, Rabin Yarangga, Dominggus A Mampioper, Angela Flassy

Timika, Jubi – Since 1972, PT Freeport Indonesia’s mining operations in Mimika, Central Papua have transformed mountains into giant ravines, pulverizing mineral-rich rocks and depositing the resulting waste, known as tailings, into rivers. While these tailings have brought fortune to many small-scale miners, they have also led to river and coastal siltation, causing problems in the region. Jubi and CNN Indonesia collaborated to shed light on the dual nature of Freeport’s tailings in a series of three reports. This is the initial installment of our collaboration.

Stenly Tuanubun (42) is busy lifting a pile of tailings sand using a shovel, then carefully transferring the sand into his filter. The filter he employs consists of a wire mesh, resembling a “mouth,” into which he pours the sand.

Gradually, he adds water to the sand, allowing the finer grains to pass through the mesh while the water carrying the tailings sand flows down onto a laid-out carpet. Over time, this carpet, typically used for worship, darkens due to the accumulation of sand.

The larger, coarser sand particles are not trapped by the small carpet and find their way into a nearby pond at the panners’ camp in Kali Kabur (Kabur River), located in Mimika Regency, Central Papua Province. Tuanubun explains that every grain of sand entering the 2 x 1 square meter pond undergoes re-filtering after a week, as he continues to extract gold from the remaining sand sourced from Freeport’s tailings.

“We [panners] call it naga,” Tuanubun told Jubi on February 4, 2023, referring to the settling remnants of the tailings in the storage pond.

The Maluku guy Tuanubun retrieved a dampened and blackened carpet saturated with tailings residue. Placing the carpet into a large pan filled with water and detergent, he utilized the laundry soap to facilitate the settling of gold particles at the bottom of the pan.

Tuanubun’s hands waved the small rug around, making sure every grain of tailings sand dissolved into the soapy water. Afterwards, he took out the rug, squeezed out the excess moisture, and stored it away.

He proceeded to gently shake the pan, removing the water little by little, which progressively revealed a dense, black composition of fine sand grains resembling a batter-like consistency.

The fine sand “batter” was transferred into a smaller pan. Tuanubun then sprinkled detergent powder over the sand and introduced a small amount of water. Using his thumbs, he slowly tapped the edges of the pan, never diverting his gaze. The gentle and repetitive tapping served to separate the black sand from the metallic mineral ore.

With utmost care, Tuanubun employed his finger to meticulously remove the black sand from the small pan, ensuring that none of the precious gold grains accompanied it. In the small pan, shimmering golden grains began to sparkle. A smile spread across Tuanubun’s face.

“This amounts to only about five or six glasses,” Tuanubun said, showing his gold results that day. His gain was approximately 0.5 grams.

The wet metal mineral ore was subsequently subjected to brief heating, lasting roughly ten seconds, until it became crusted dry. Tuanubun then prepared to sell the gold from the panning to the “gold shops” on Jalan Ahmad Yani in Timika.

Thousands of panners of indigenous tribes

Freeport has been engaged in extensive mining operations in Mimika since 1972. In 1988, they discovered the Grasberg gold deposit, and since then, they have been using large-scale mining equipment to extract gold, silver, and copper minerals from the mountain. As a result, Mount Grasberg, situated at an altitude of approximately 4,000 meters above sea level, has been transformed into a massive excavation.

According to Freeport’s 2015 Fact Sheet on Sirsat – Mine Waste Sand, the company employs a physical flotation process to separate economically valuable copper and gold minerals from non-valuable rock particles. This process generates a concentrate rich in copper and gold. This material represents only 3 percent of the total mining rock processed.

The remaining 97 percent of material, which Freeport considers to have no economic value, raises the question of what happens to it. In a document titled “Management of Tailings” published by Freeport in 2009, it is stated that these tailings are disposed of in a deposition area covering 23,000 hectares

Tony Wenas emphasized that the disposal of tailings into the Ajkwa and Otomona Rivers is done in compliance with government permits. He cited a series of permits obtained by Freeport for the dumping of tailings in the lowlands of Mimika, including the Irian Jaya Governor’s Decree No. 540/154/SET dated January 4, 1995, the Irian Jaya Governor’s Decree No. 540/2102/SET dated June 20, 1996, and the Environmental Impact Analysis (AMDAL) document 300K in 1997, as indicated in the Minister of Environment’s Decree No. KEP.-55/MENLH/12/1997.

Freeport has obtained various permits to continue discharging tailings into the watershed and coastal areas of Mimika. These permits include Mimika Regent Decree No. 4/2005, Minister of Environment Decree No. 431/2008, Minister of Environment and Forestry Decree No. 175/Menlhk/PLB.3/4/2018, Minister of Environment and Forestry Decree No. 594/MENLHK/SETJEN/PLA.0/12/

The deposition area, known as the Modified Ajkwa Deposition Area, has been attracting panners from various parts of the archipelago since 1996. Surprisingly, these panners have discovered that the supposedly “economically worthless” tailings contain a significant amount of gold.

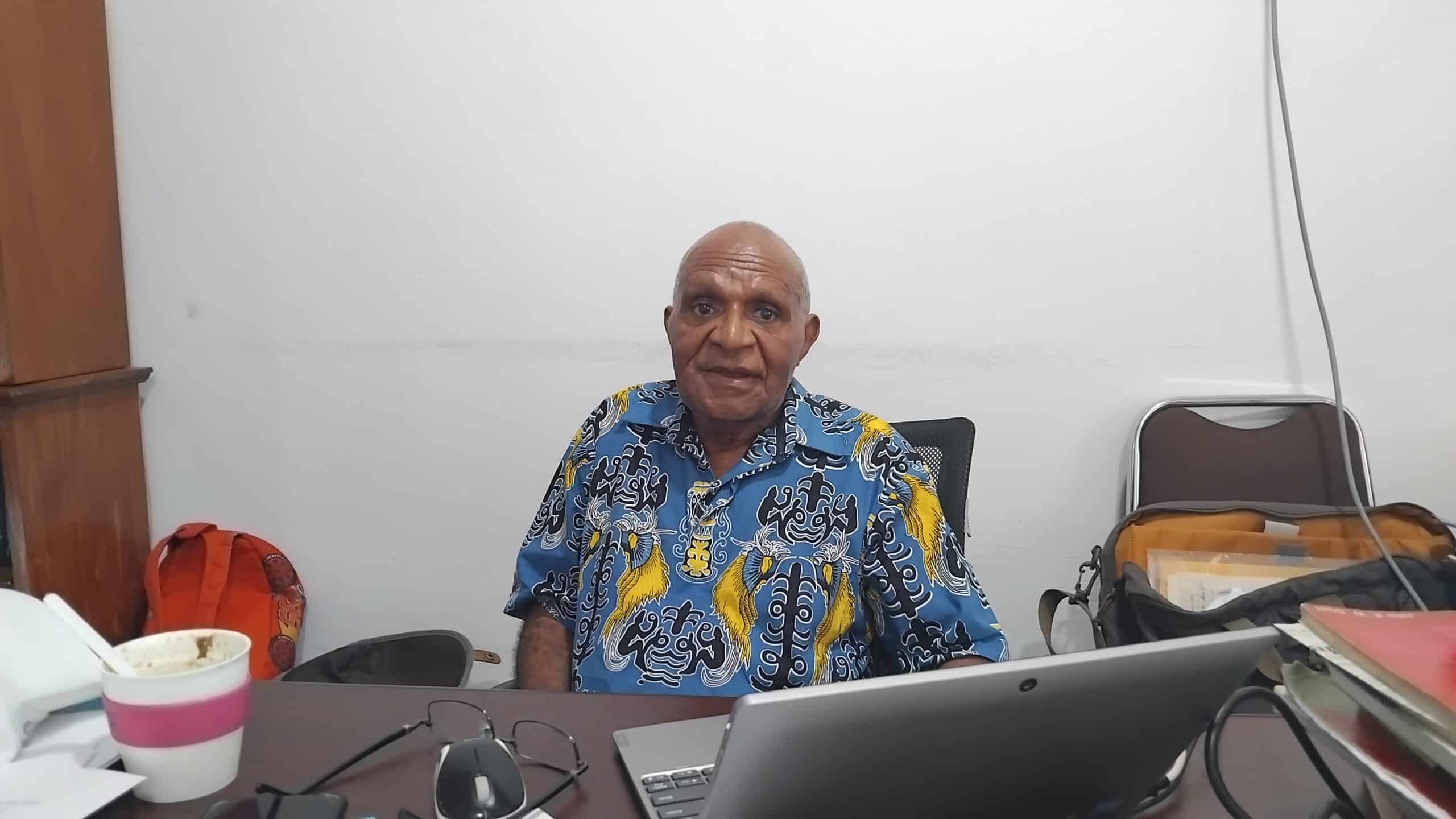

Simon Rahajaan, chairman of the Gold Panners Association in Timika, said there was a significant presence of panners in the Dimodificated Ajkwa Deposition Area. This area attracts thousands of panners from diverse ethnic backgrounds, including the Manggarai, Flores, Bugis, Makassar, Toraja, Manado, Buton, Maluku, Java, and Indigenous Papuans.

The Gold Panners Association in Timika estimates that around 4,000 to 5,000 individuals depend on panning activities in the Freeport’s tailings area to sustain their livelihoods. Additionally, there is a division of the panning area among the panners.

Indigenous Papuans, particularly the Amungme and Kamoro groups, have their own panning areas. Simon Rahajaan explained that the Amungme people have more panning areas in the Banti region, which happens to be where Freeport initially disposed of their tailings. This explains the presence of panning camps in the Mile 72 area.

On the other hand, the Kamoro people are mostly found around Mile 21, but they do not construct camps there. Instead, they regularly travel back and forth between the location.

“They leave in the morning, return in the afternoon, and sell the results of their panning activities,” Rahajaan told Jubi on January 31, 2023.

According to Rahajaan, the gold yield here is highly promising and attracts numerous individuals. Engaging in panning work does not necessitate fulfilling administrative requirements, but only requires physical capital.

Rahajaan mentioned that panners come from diverse backgrounds, ranging from those who haven’t completed elementary school to those holding university degrees.

“They are tempted by the substantial outcomes from a job that doesn’t involve administrative procedures, diplomas, applications, or Police Record Certificates. All they need to earn money is physical readiness,” he explained.

Scattered camps around the tailings area

Stenly Tuanubun and his wife made the decision to leave Maluku Province’s Tual City, located in the southeastern part of the Maluku Islands, and move to Timika. Their motivation for this was the alluring prospect of finding gold through tailings panning.

Panners from Timika City can easily reach the desired location by using their own motorcycles or renting a motorcycle taxi for Rp 10,000 (US$ 0.67) to Kwamki Lama Village.

Kwamki Lama serves as a central hub or “base” for panners operating in the lowlands. From there, panners have to walk for approximately 20 minutes to reach Kali Kabur, which is referred to by panners as the Ajkwa River.

To reach Kali Kabur, panners must navigate through a wide river with swift currents, ultimately leading them to the dulang (panning) site. In the delta area between the crystal-clear river and Kali Kabur, numerous camps have been established by panners.

These camps resemble semi-permanent workers’ barracks, featuring tarpaulin roofs and walls made of either tarpaulin or used zinc sheets. Each “barrack” accommodates two to five individuals, while some families, like Tuanubun’s, construct their own “huts”. Tuanubun proudly mentioned that he built his own 5 x 6 meter “hut”.

His hut features a tin roof, and most of its walls are covered with tarpaulin. Only the front of the hut is made of clapboard. Tuanubun and his wife Linda reside in the hut, while their three children remain in Tual.

Living in this setting enables Tuanubun to save Rp 500,000 (US$ 33.42) per week. Every two weeks, he travels to Timika to sell the gold he has collected. He acknowledges that within a two-week period, he typically gathers around 5 to 6 grams of impure gold powder.

“I don’t find gold every day. Usually, when the location is good, the results are promising,” he added.

Another gold panner, Nus Key (53), has been involved in this activity since 1997. Over the course of 26 years, he has relocated several times, panning for tailings in different areas such as Mile 58, Mile 53, and currently settling in Mile 28.

Key mentioned that he has only been panning at Mile 28 for five months. In the past, he constructed a hut along the banks of the Kali Kabur, but it frequently suffered from flooding.

In the Mile 28 area, he built a 5 x 7 meter hut. The hut consists of a single room with an open kitchen.

Nus Key considers gold panning to be a lucrative endeavor. He emphasizes that perseverance is key for panners to achieve results.

“Panning offers a fast-paced lifestyle. It is a quick way to earn money. Today, we go panning in the morning, and usually by the afternoon, we already have money. Other jobs like working in construction, for example, take a long time to see the fruits of your labor. But with gold panning, once you find gold, it means having money in the afternoon,” he explained.

Nus Key says he can earn up to 4 grams of gold a week, which he can sell for around Rp 2.5 million (US$ 166). After deducting expenses for necessities such as rice, coffee, sugar, cigarettes, and gasoline for his equipment, Nus Key can retain more than half of that amount as his net income.

“I work alone. My family is all in Timika City. During holidays, however, my children join me and help me panning,” he said.

Another person engaged in gold panning is Zakarias Waer, a 42-year-old man operating in the Mile 28 area. Waer has been involved in gold panning since 2006, having left his hometown in Maluku.

Originally from Tual, Waer explained that his family had initially ventured into tailings panning and reported favorable outcomes. This motivated him to follow suit and relocate to the current area, where he joined his community of fellow gold panners.

According to Waer, the gold panning yields in 2006 were significantly better. During that period, he was able to obtain around 20 grams of gold per week, which could be sold for a purchase price of Rp 300,000 per gram. With this level of productivity, he could earn Rp 6 million per week.

However, nowadays, Waer can only extract approximately 2 grams of gold per week.

“Comparing the results from before and now, it is clear that there was more money back then. Nowadays, we are grateful if we can earn around Rp 1.3 million a month,” he said, adding that his physical condition affects his work schedule, allowing for about three days of work and three days of rest in a week at most.

A blessing of fortune for many

The presence of panners like Stenly Tuanubun, Nus Key, and Zakarias Waer is sustained by numerous gold shops in Timika. Referred to as “powder shops” by the panners, these establishments differ from typical jewelry stores. Instead of selling gold jewelry, the gold shops in Timika serve as collectors for the panning results of thousands of tailings panners affiliated with PT Freeport Indonesia.

Muhammad Thahir, one of the gold entrepreneurs in Timika, disclosed that he purchases gold from around 16 to 20 panners each day. The lucrative nature of the gold panning business prompted Thahir to relocate from Makassar in 2005 and establish his gold business in Timika.

“I moved from Makassar to Timika to work in the gold industry. My parents were involved in crafting gold jewelry, importing it from China and creating necklaces and bracelets. I have been in Timika since 2005 until today,” Thahir told Jubi on February 1, 2023.

Thahir, who is also the chairman of the Gold Entrepreneurs Association in Timika, revealed that there are at least fifty gold shops that engage in purchasing tailings gold pans. He mentioned that the practice of receiving gold pans began in 1996 when the price of gold experienced a significant surge. “At that time, in 1996, the price of gold skyrocketed,” he said.

Thahir admitted that between 2005 and 2007, he was able to acquire as much as 50 grams of gold per day, totaling up to 300 grams per week. However, he emphasized that the purchase volumes are relative, as they fluctuate based on the availability of gold.

“If we were to calculate it on a weekly basis, there were instances when we purchased 300 grams when there was a substantial supply,” Thahir explained.

He further acknowledged that the quantity of gold obtained from the panners has progressively diminished. These days, he only acquires around 1 gram of gold per day, with a maximum of approximately 10 grams per week.

He stated that the decrease in the quantity of gold can be attributed to some panners switching to other jobs, as well as the increasing number of gold shops in Timika Regency.

“Starting from January 2023, my colleagues and I can only acquire around 10 grams, if there’s any. To be honest, there’s practically nothing at the moment. If I were to discuss the sales volume, particularly at my shop, it is relative. It used to be bustling, but now it has declined a bit. Many panners have returned to their respective villages, so the volume of panning product purchases has dramatically dropped,” he explained.

Thahir mentioned that gold from panners is typically bought at a minimum price of Rp 350,000 per gram, while the highest price ranges from Rp 600,000 to Rp 700,000 per gram. The pricing is estimated based on the purity of the gold powder brought by the panners.

“Everywhere, the gold is assessed to determine whether the items meet the desired quality or fall below the standard. That’s when a price agreement is reached. Some items are of good quality, some are not, and some are mixed. We offer a higher price for good-quality items, but every item we purchase is still impure and requires refinement as it is not pure gold,” Thahir clarified.

Tuanubun relies on these gold shops. He acknowledges that the price of gold is constantly fluctuating, which directly impacts his earnings. However, he is still grateful for the gold shops as they greatly assist the panners.

Tuanubun consistently sets aside approximately Rp 7 million per month from his income to support his children’s education in Tual. He expressed his hope that the gold shop would continue operating and purchasing his gold products.

“I am extremely content conducting business with the gold shops. They are very helpful because we can sell our panning results there,” Stenly remarked.

Nus Key shared that the income he earns from gold panning helps support his family’s daily expenses and provides for his children’s education, even up to university. Panning has played a significant role in improving their lives.

“Money from gold panning covers our school expenses. Our family’s needs and our children’s education are supported by the earnings from panning. Especially for the community in Timika, panning enables children to go to school. Many individuals graduate and earn a living through panning. This has contributed to the development of Timika’s economy as thousands of people are involved in gold panning,” Nus Key explained.

Meanwhile, Zakarias Waer’s family has also experienced prosperity through his work as a gold panner. After seventeen years in the industry, Waer has managed to purchase land, build a house, and support his three children. He has also financed his younger siblings’ education.

“When I was panning, my wife and I lived in a rented room. As soon as I had some money, I decided to contribute it to the cooperative. I have been paying my children’s school fees with the earnings from panning up to this day. The benefits of gold panning are extensive. My younger brother is studying architecture, my sister has a degree in healthcare, and my youngest sibling has a law degree,” Waer shared.

He continues to save a portion of his income from tailings panning. He invests some of his earnings in pig farming as a secondary source of income.

“Considering the uncertainty of life, I thought it would be wise to have another source of income. That’s why I started raising pigs,” he added.

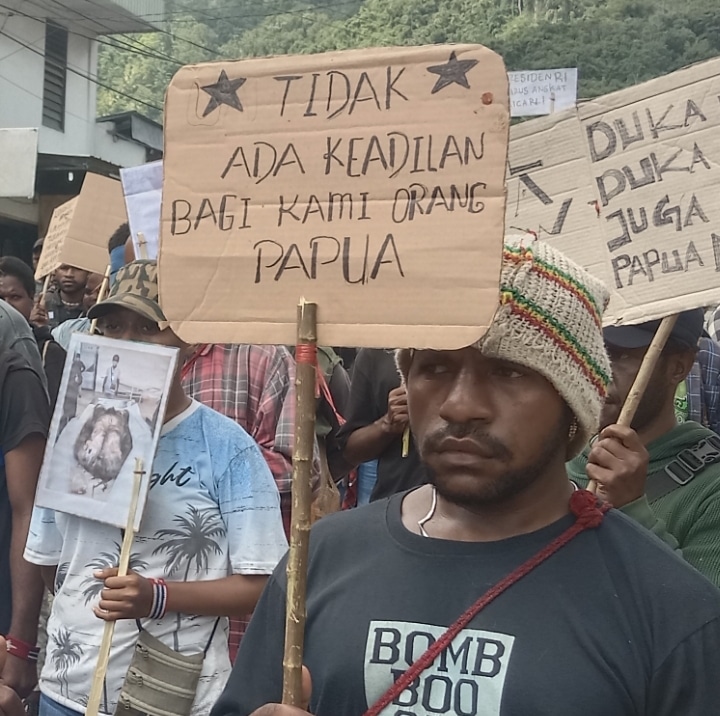

Big fortune, big risk

The fortune in tailings panning comes with significant risks as the activity lacks legal protection and regulation for the panners. Zakarias Waer is well aware of the dangers involved. He acknowledged that some panners have lost their lives when swept away by strong river currents while attempting to cross the water.

Many panners suffer from skin diseases, wounds, and peeling as a result of their work. Waer himself experienced an episode of water fleas.

His wife, Rina Waer, recognizes the high risks associated with her husband’s job. “All I can do is pray. While taking care of the children at home, I pray for my husband’s safety as he works at the river panning to provide for our household and children’s education. I hope we can afford to send our children to college for their future,” she expressed.

Rina admitted that she cannot rest peacefully when it rains because it often leads to flooding in the panning location. “When it rains like this, I anxiously call my husband to ask if there is flooding. If he confirms it, we stay on alert and cannot sleep,” she said.

Panning activities have also faced allegations of mercury pollution in Mimika waters, although there is denial from all parties involved regarding the use of heavy metals in tailings panning. Jubi’s investigation did not find any evidence of mercury use among the panners they encountered in the field.

Nus Key affirmed that he and other panners do not use mercury in their gold panning process. According to Nus Key, they are hazardous and causes the skin on their hands to peel. Additionally, using mercury can sometimes damage the gold. He stated that panners solely rely on Rinso, a common detergent brand, to extract gold.

“We use Rinso soap. If we use mercury, it ruins the gold. Panners lose out if they use mercury because it turns the gold into crushed dust. Using mercury is illegal and dangerous,” Nus Key explained.

Zakarias Waer also attested that he only utilizes detergent to purify the gold during his panning work. “We only use soapy water and shake it by hand. Afterwards, we collect the purified gold and sell it to the gold shop,” he described the process.

Despite the risks involved, Waer and his wife Rina recognize that the rewards are worth it. Their three children are currently attending elementary and junior high school in Timika City.

Gold Panners Association in Timika chair Simon Rahajaan expressed their efforts to establish regulations to provide legal protection for panners. However, they have been unsuccessful thus far as the panning area falls within the Freeport Project Area, which is considered a national vital object.

Regional regulations cannot be enacted in this area, and only Freeport employees are permitted access. Despite this, people have still managed to enter and extract value from Freeport’s waste.

Rahajaan highlighted the physical toll that panning takes on the panners, causing their skin to peel, starting from the crevices of their hands and feet. The long-term health implications are uncertain, and the act of crossing the river itself is a challenging ordeal. Those unaccustomed to it may slip and fall.

Muhammad Jambia Wadan Sao, the Head of Legal Affairs at the Mimika Regency Secretariat, confirmed the absence of regulations governing community panning activities in the Freeport area. As of January 27, 2023, there are no specific rules in place to regulate the activities of individuals within the Freeport area, according to Jambia.

According to Jambia, the Mimika Administration could not immediately establish regulations to govern the activities of panners in the Freeport area due to its status as a national vital object. Jambia acknowledged the complexity of creating regulations, as the area is restricted and not accessible to everyone.

He admitted to being unaware of who granted permission to the community for panning in Freeport’s area. He said access to the area is restricted from Mile 32 onwards. The panners’ presence there suggests they may have received permission from Freeport or obtained access through other means.

The Mimika Administration previously issued Mimika Regent Decree No. 120/2009, forming a team to handle panners in Freeport’s area. The team’s responsibilities included gathering data on panner locations, documenting their conditions, and formulating measures to address the issue.

Jambia highlighted that accidents, including fatalities from flooding, occur frequently in those areas. Additionally, conflicts between panners are common.

Simon Rahajaan emphasized that Freeport’s tailings panning should not be halted without providing alternative employment opportunities for the thousands of panners. Banning the activity without offering viable alternatives could lead to new social problems. According to Rahajaan, the government must prepare job opportunities before considering a ban.

However, allowing panning to continue without regulations poses its own problems. Thousands of panners work under high-risk conditions without legal certainty, safety measures, or decent working conditions. (*)